The Machinist

- Thread starter Lanx

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

latheboy

Trakanon Raider

- 887

- 1,112

Haha,

Not to lazy be the way.. Dial up speeds yesterday prevented me from adding video content so didn't both..

I'm a toolmaker. I make shinny stuff on lathes and milling machines. Use CAD programs.

Here a cool 5 axis CNC making a helmet.

My current project is a downhill mountain bike. Designed in cad and then made a heap of parts.

Everything machined on manual machines cause we don't have any CNC's.

Not to lazy be the way.. Dial up speeds yesterday prevented me from adding video content so didn't both..

I'm a toolmaker. I make shinny stuff on lathes and milling machines. Use CAD programs.

Here a cool 5 axis CNC making a helmet.

My current project is a downhill mountain bike. Designed in cad and then made a heap of parts.

Everything machined on manual machines cause we don't have any CNC's.

- 5

- 1

I took a couple AutoCAD classes, and Inventor. Have to say I felt Inventor was easier to work with. I never took Rhino, Solidworks, etc

It's surprisingly difficult to find videos of machining the parts I'm familiar with online. A lot of it is just either boring & keying, or boring & tapping.

It's surprisingly difficult to find videos of machining the parts I'm familiar with online. A lot of it is just either boring & keying, or boring & tapping.

latheboy

Trakanon Raider

- 887

- 1,112

What do you do

Erronius

?

Erronius

?

Well he is doing it the hard way.

I thread turn LH a far bit making bottom brackets for push bikes.

1 RH and 1 LH on the same part.

The easiest way is leave the tool in the normal cutting direction, turn the chuck in the normal direction and just reverse the feed so you are cutting from the inside to out.

I also do not disconnect the lead screw, once out move the tool and reverse the chuck direction so the cutter goes back in.

Stop without crashing and reset the tool depth and go again.

It's easy to get the timing on the lead screw wrong and smash stuff.

Well he is doing it the hard way.

I thread turn LH a far bit making bottom brackets for push bikes.

1 RH and 1 LH on the same part.

The easiest way is leave the tool in the normal cutting direction, turn the chuck in the normal direction and just reverse the feed so you are cutting from the inside to out.

I also do not disconnect the lead screw, once out move the tool and reverse the chuck direction so the cutter goes back in.

Stop without crashing and reset the tool depth and go again.

It's easy to get the timing on the lead screw wrong and smash stuff.

latheboy

Trakanon Raider

- 887

- 1,112

I bought a 3D printer a couple of years ago for $500 i think.

3D Printer Touch – Cocoon Products

Basic as but good for kids toys and dragon dildos.

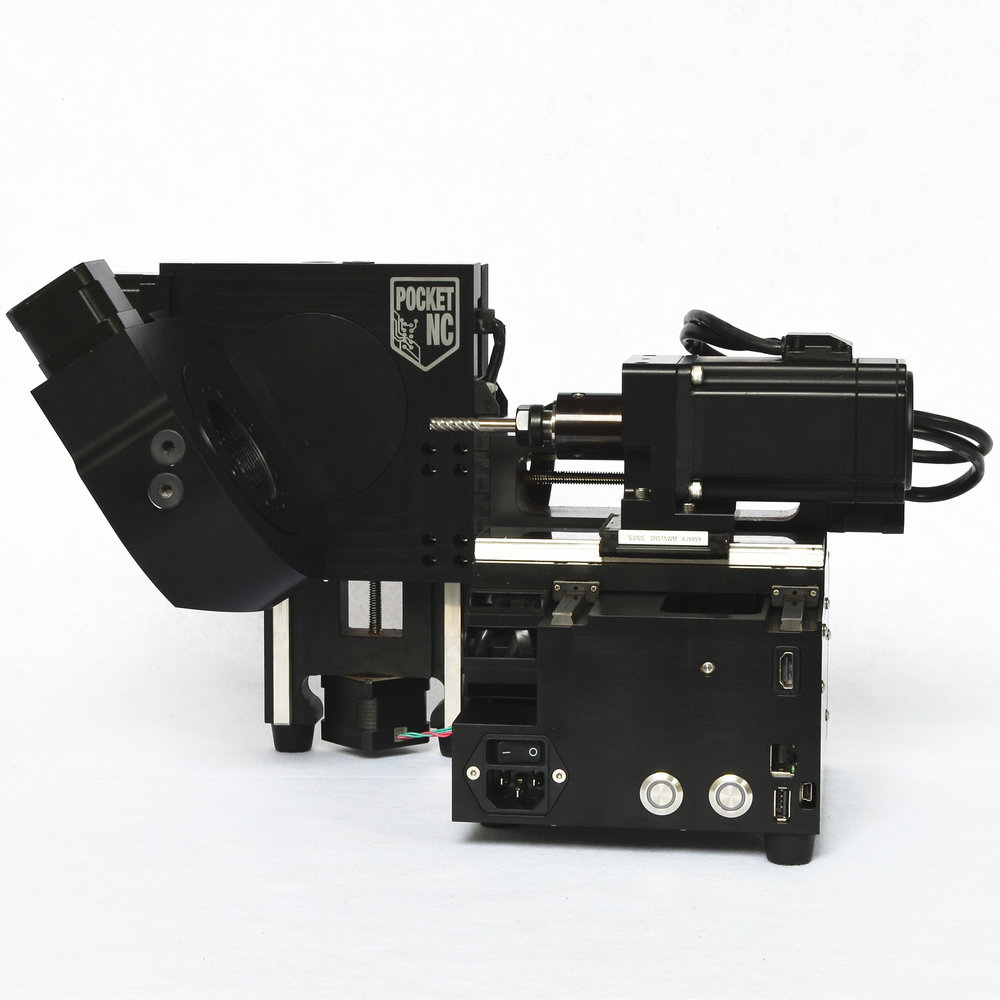

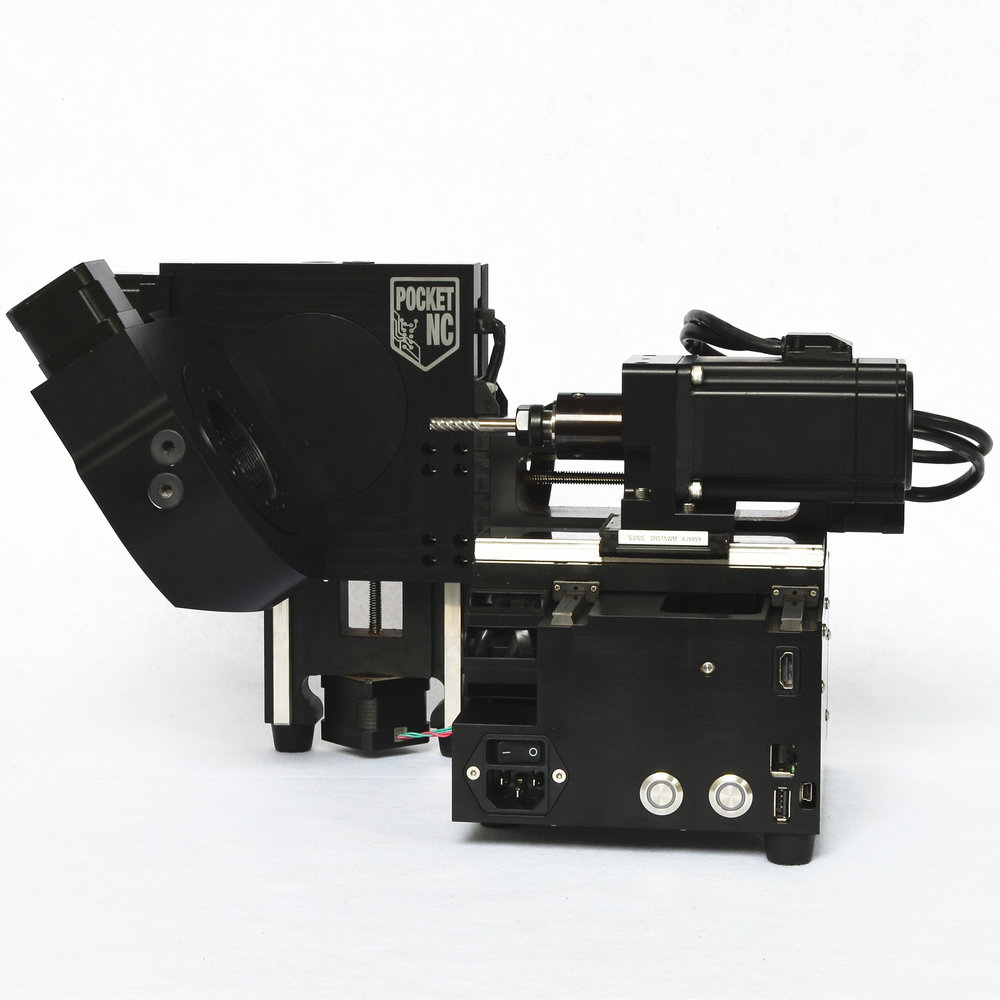

Desktop machines have come a long way in the last 5 years to where you can buy stuff like this.

This is just 1 example from a 5 minute search.

Pocket NC V2

5 axis (X 5", Y 5" Z3.55")

But for $5500 i think i'll wait and just keep using a real CNC

Still interesting to see what is coming out for the hobby guys.

3D Printer Touch – Cocoon Products

Basic as but good for kids toys and dragon dildos.

Desktop machines have come a long way in the last 5 years to where you can buy stuff like this.

This is just 1 example from a 5 minute search.

Pocket NC V2

5 axis (X 5", Y 5" Z3.55")

But for $5500 i think i'll wait and just keep using a real CNC

Still interesting to see what is coming out for the hobby guys.

I was an electrician, but moved over to a company that does industrial instrumentation, valves, actuators, etc. I still do wiring in the shop, but I end up doing a bit of everything.What do you doErronius ?

The pieces we use that are similar to the piece in the video usually act as an adapter between a valve, and either a gearbox or an actuator. They just need to be machined to match the specific thread type on a valve stem, or bored and keyed for quarter-turn valves (butterfly valves are quarter turn, because they usually only move 90 degrees between open and closed)

This is a pic of one sort of

I have some random pics on a phone I'll have to upload this weekend, maybe.

This company has a picture gallery, with a 'machining' section that is probably similar to what we do. Adaption plates, special couplers, torque/stem nuts, etc.

Edmonton Valve Actuation Design Company - Gledhill Steel Products Ltd.

Borzak

<Bronze Donator>

- 28,015

- 37,881

I can't be of any help. The only machining we do is on a type of machine they don't make anymore I don't think. Vertical lathe made for doing driveshaft and flange work in WWII. Still going strong and does what we need for turning plate we cut on the plasma table to manway flanges and pipe flanges up to 6' diameter quick and dirty.

Last edited:

- 1

latheboy

Trakanon Raider

- 887

- 1,112

I was talking to the old guys at work a while ago, here in Australia I'm possibly the last of the toolmaker generation. They (the old guys) know more than I could ever hope to.. I'm trying to get them to write down their secrets so its not lost forever

- 3

Share: