Woodworking

- Thread starter Intrinsic

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can I get some tips?

Here is the current status of this table...and I'm going to turn this into a template to use in the future so I'm looking for ideas that make it easy to do a bunch more with most of the cutting being done on the CNC.

24x24 sheet. The map with resin is 20x20. The outter border/lip is 1in, and surfaced -0.5in below the top of the map.

The border in the bottom left is just a test piece I cut out of a 2x4. The bottom is notched to fit that 1in x 0.5in lip, and I drilled it and put in M5 threaded inserts.

I'm planning to drill the apron and then screw those in to the bottom. So, the lip of the plywood with map will be sandwiched between the borders on top and the apron on bottom, glued and screwed.

I like the look of the last contour table I did and want to do the legs and apron the same way.

Any creative way to join the legs to the apron, that I can do on the CNC easily....hopefully without rotating pieces?

This hardware is my best idea so far but it'd be cool to do without any hardware other than the bolts and inserts.

Making a few custom jigs for dowels wouldn't be too bad either, but it would be nice having the option to remove the legs like I'd get with the hardware.

Mortis and tennon is kind of a long term goal, but I need to set up a better router station to do that, or finish my new CNC bed with a grid of threaded inserts (to help with alignment when rotating pieces).

Just wanted to see if anyone had ideas for clever machining methods to do this?

Here is the current status of this table...and I'm going to turn this into a template to use in the future so I'm looking for ideas that make it easy to do a bunch more with most of the cutting being done on the CNC.

24x24 sheet. The map with resin is 20x20. The outter border/lip is 1in, and surfaced -0.5in below the top of the map.

The border in the bottom left is just a test piece I cut out of a 2x4. The bottom is notched to fit that 1in x 0.5in lip, and I drilled it and put in M5 threaded inserts.

I'm planning to drill the apron and then screw those in to the bottom. So, the lip of the plywood with map will be sandwiched between the borders on top and the apron on bottom, glued and screwed.

I like the look of the last contour table I did and want to do the legs and apron the same way.

Any creative way to join the legs to the apron, that I can do on the CNC easily....hopefully without rotating pieces?

This hardware is my best idea so far but it'd be cool to do without any hardware other than the bolts and inserts.

Making a few custom jigs for dowels wouldn't be too bad either, but it would be nice having the option to remove the legs like I'd get with the hardware.

Mortis and tennon is kind of a long term goal, but I need to set up a better router station to do that, or finish my new CNC bed with a grid of threaded inserts (to help with alignment when rotating pieces).

Just wanted to see if anyone had ideas for clever machining methods to do this?

Captain Suave

Caesar si viveret, ad remum dareris.

- 5,926

- 10,168

Making a few custom jigs for dowels wouldn't be too bad either, but it would be nice having the option to remove the legs like I'd get with the hardware.

Mortis and tennon is kind of a long term goal, but I need to set up a better router station to do that, or finish my new CNC bed with a grid of threaded inserts (to help with alignment when rotating pieces).

Just wanted to see if anyone had ideas for clever machining methods to do this?

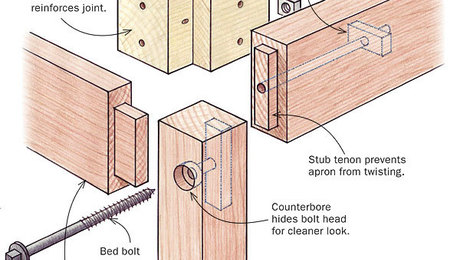

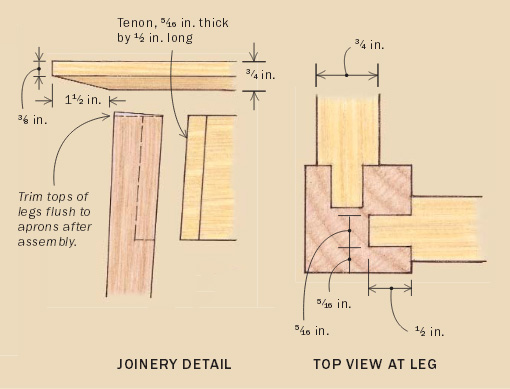

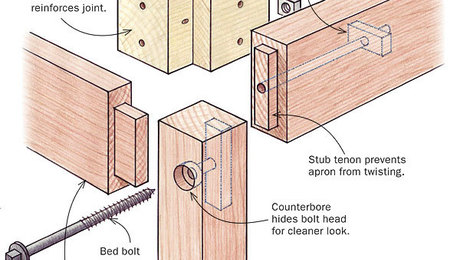

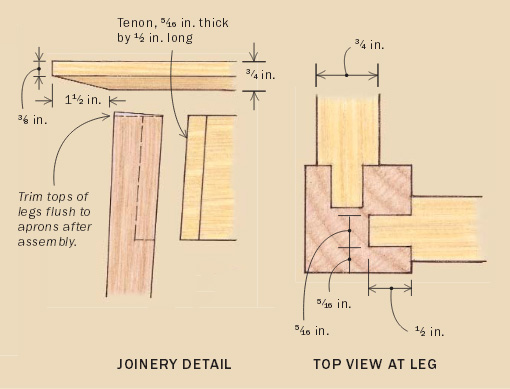

IMO this is a more structurally sound knock-down hardware setup than a single bracket. (Yes, it has mortise/tenon but those are the gold standard for a reason):

Use Bed Bolts for a Knock-Down Table - FineWoodworking

Q: I’ve been asked to make a 9-ft.-long harvest table that can be disassembled for easy moving. What is the best way to join the aprons to the legs so […]

If you don't care about the knock-down feature, it's pretty easy (and good practice) to just go with open mortises with just a saw, chisel, and maybe a handheld router to hog out the waste.

- 2

Well that looks even more complicated than the options I was thinking of, lol. How the hell do people make money making furniture? Just the materials is about $300-$400, to say nothing of the labor. Hoping to find an approach that doesn't require a ton of work with chisels or different stations.IMO this is a more structurally sound knock-down hardware setup than a single bracket. (Yes, it has mortise/tenon but those are the gold standard for a reason):

Use Bed Bolts for a Knock-Down Table - FineWoodworking

Q: I’ve been asked to make a 9-ft.-long harvest table that can be disassembled for easy moving. What is the best way to join the aprons to the legs so […]www.finewoodworking.com

If you don't care about the knock-down feature, it's pretty easy (and good practice) to just go with open mortises with just a saw, chisel, and maybe a handheld router to hog out the waste.

Captain Suave

Caesar si viveret, ad remum dareris.

- 5,926

- 10,168

How the hell do people make money making furniture?

They don't unless they find rich customers willing to pay thousands of dollars for the cost of labor. Cost-sensive people buy bullshit from Ikea.

Hoping to find an approach that doesn't require a ton of work with chisels or different stations.

That's just the nature of the craft. The easy solutions mostly suck.

- 1

Burns

Avatar of War Slayer

First idea for the water ways, and maybe roads to eliminate hand painting, when I saw the piece before:Can I get some tips?

Here is the current status of this table...and I'm going to turn this into a template to use in the future so I'm looking for ideas that make it easy to do a bunch more with most of the cutting being done on the CNC.

View attachment 468528

24x24 sheet. The map with resin is 20x20. The outter border/lip is 1in, and surfaced -0.5in below the top of the map.

The border in the bottom left is just a test piece I cut out of a 2x4. The bottom is notched to fit that 1in x 0.5in lip, and I drilled it and put in M5 threaded inserts.

I'm planning to drill the apron and then screw those in to the bottom. So, the lip of the plywood with map will be sandwiched between the borders on top and the apron on bottom, glued and screwed.

I like the look of the last contour table I did and want to do the legs and apron the same way.

Any creative way to join the legs to the apron, that I can do on the CNC easily....hopefully without rotating pieces?

This hardware is my best idea so far but it'd be cool to do without any hardware other than the bolts and inserts.

View attachment 468530

Making a few custom jigs for dowels wouldn't be too bad either, but it would be nice having the option to remove the legs like I'd get with the hardware.

Mortis and tennon is kind of a long term goal, but I need to set up a better router station to do that, or finish my new CNC bed with a grid of threaded inserts (to help with alignment when rotating pieces).

Just wanted to see if anyone had ideas for clever machining methods to do this?

- Use the CNC to cut the river channel in the uncut board first.

- Fill those channels with the "water" tinted epoxy.

- Then cut the topographic map, milling the epoxy with the wood.

Alternatively, you could cut all the way through the wood, use the epoxy to join the pieces of wood back together, then add a light under it to light up the water. Might sound better in my head than it would actually look though.

I think you could do the mortise and tenon pretty easily once you get the process set up and a secure jig. Either with the CNC (maybe, I have no idea how CNC works) or your own plunge router. If you have a consistent apron and leg then you're just batching pieces out and have minimal setup, teardown, and reconfiguration.

Coincidentally this month's issue of Fine Woodworking has an article just on this topic called "Quick and Accurate Mortises" by Bob Van Dyke showing how to build a router box.

Coincidentally this month's issue of Fine Woodworking has an article just on this topic called "Quick and Accurate Mortises" by Bob Van Dyke showing how to build a router box.

- 3

That's exactly how I did this oneFirst idea for the water ways, and maybe roads to eliminate hand painting, when I saw the piece before:

Main issues being the added cost of epoxy, which will mostly get cut away, and whether the epoxy would stay affixed to wood, once it starts to get thin, at the bottom.

- Use the CNC to cut the river channel in the uncut board first.

- Fill those channels with the "water" tinted epoxy.

- Then cut the topographic map, milling the epoxy with the wood.

Alternatively, you could cut all the way through the wood, use the epoxy to join the pieces of wood back together, then add a light under it to light up the water. Might sound better in my head than it would actually look though.

- 1

Burns

Avatar of War Slayer

Oh, nice. I must have misread something then; thought you were brushing it in.That's exactly how I did this one

Borzak

<Bronze Donator>

- 27,962

- 37,806

The radial arm saw? Those are neat tools if you use them properly. The old use case documentation is written by sone hilarious evil genius.

Or did you mean the shaper he used to finish the cheeks? I think that was actually a giant router bit that looks like a blade.

Used to see them quite often in shops and people had them at home. They had a bad record of cutting off someones arm that wasn't paying attention.

On the topic of how do people make money making furniture. No idea. Not everyone but a lot of people have lost all touch with what counts as quality. Not just furniture but a lot of things. Even people with money see a lot of stuff is "it's the cheapest" or "I can buy another if this one falls apart".

That's what I'm working up to. I'm in wine country and these people LOOOOOOOVE their vineyard properties.

I'm actually working on a vineyard layout right now at work. I just don't want to try to sell tables to my clients at work by pitching it, so I might make a free one for the wine grower's alliance to put in their building. Vineyards are my favorite projects because they're beautiful and there's plenty of money in it. No nickel and diming, and they appreciate pretty stuff/extravagance.

I'm actually working on a vineyard layout right now at work. I just don't want to try to sell tables to my clients at work by pitching it, so I might make a free one for the wine grower's alliance to put in their building. Vineyards are my favorite projects because they're beautiful and there's plenty of money in it. No nickel and diming, and they appreciate pretty stuff/extravagance.

- 1

- 1

Captain Suave

Caesar si viveret, ad remum dareris.

- 5,926

- 10,168

Not everyone but a lot of people have lost all touch with what counts as quality. Not just furniture but a lot of things. Even people with money see a lot of stuff is "it's the cheapest" or "I can buy another if this one falls apart".

That's how I got into the hobby in the first place. I had a bunch of Ikea shit that shortly failed and I thought to myself, "Real furniture is crazy expensive, but I could totally do better than this on my own." So I watched a lot of guys on YouTube (Paul Sellers, Rob Cosman, etc.), and then I did. Now 6-7 years in working at a glacial pace I might have actually saved myself the cost of my tools. =)

Last edited:

- 2

whoo

<Silver Donator>

Easy and cheap: If you want easy, and you have reasonably chunky legs where they meet the aprons, you could use pocket screws.Can I get some tips?

Here is the current status of this table...and I'm going to turn this into a template to use in the future so I'm looking for ideas that make it easy to do a bunch more with most of the cutting being done on the CNC.

View attachment 468528

24x24 sheet. The map with resin is 20x20. The outter border/lip is 1in, and surfaced -0.5in below the top of the map.

The border in the bottom left is just a test piece I cut out of a 2x4. The bottom is notched to fit that 1in x 0.5in lip, and I drilled it and put in M5 threaded inserts.

I'm planning to drill the apron and then screw those in to the bottom. So, the lip of the plywood with map will be sandwiched between the borders on top and the apron on bottom, glued and screwed.

I like the look of the last contour table I did and want to do the legs and apron the same way.

Any creative way to join the legs to the apron, that I can do on the CNC easily....hopefully without rotating pieces?

This hardware is my best idea so far but it'd be cool to do without any hardware other than the bolts and inserts.

View attachment 468530

Making a few custom jigs for dowels wouldn't be too bad either, but it would be nice having the option to remove the legs like I'd get with the hardware.

Mortis and tennon is kind of a long term goal, but I need to set up a better router station to do that, or finish my new CNC bed with a grid of threaded inserts (to help with alignment when rotating pieces).

Just wanted to see if anyone had ideas for clever machining methods to do this?

Easy, not cheap: find a used Festool Domino DF500. They are $600 new, but it's an instant tenon machine thats almost foolproof. Think dowels but square and better. If you can get ones used in good working condition for $300, it would be a good solution. The floating tenons are about 60 cents each and made of beech. They come in different sizes.

Cheap, not easy: learn to cut mortise & tenon by hand. All you need is a tenon saw, 2 chisels, and a #4 hand plane. All can be had at garage sales/ebay.

Free (maybe?) : depending on your CNC, if you can rig up a vertical clamping station within the XY area of the machine bed, you could cut M&T.

Good luck!

- 1

Thanks whoo! Good advice. I'll go look into these tonight.Easy and cheap: If you want easy, and you have reasonably chunky legs where they meet the aprons, you could use pocket screws.

Easy, not cheap: find a used Festool Domino DF500. They are $600 new, but it's an instant tenon machine thats almost foolproof. Think dowels but square and better. If you can get ones used in good working condition for $300, it would be a good solution. The floating tenons are about 60 cents each and made of beech. They come in different sizes.

Cheap, not easy: learn to cut mortise & tenon by hand. All you need is a tenon saw, 2 chisels, and a #4 hand plane. All can be had at garage sales/ebay.

Free (maybe?) : depending on your CNC, if you can rig up a vertical clamping station within the XY area of the machine bed, you could cut M&T.

Good luck!

I wasn't even thinking about pocket screws because y'all are shaming monsters....but is there a version that does bolts & threaded inserts the same way? I think I like that idea if that's a thing. No idea how strong it would be though.

whoo

<Silver Donator>

I'm not aware of a threaded insert/bolt system that works like pocket screws.

I know there is a lot of shaming about pocket screws. While M&T is the best solution for strength and longevity in this application, the pocket screws are plenty strong. And since you would be putting two screws vertically into the leg along the grain, there wouldn't be any expansion /contraction to worry about.

A bit of glue and the pocket screws hidden on the inside would be fine. Kreg even makes a pocket plug cutter so you can plug the pocket holes with the same wood you use for the apron.

I know there is a lot of shaming about pocket screws. While M&T is the best solution for strength and longevity in this application, the pocket screws are plenty strong. And since you would be putting two screws vertically into the leg along the grain, there wouldn't be any expansion /contraction to worry about.

A bit of glue and the pocket screws hidden on the inside would be fine. Kreg even makes a pocket plug cutter so you can plug the pocket holes with the same wood you use for the apron.

- 1

Captain Suave

Caesar si viveret, ad remum dareris.

- 5,926

- 10,168

Festool Domino DF500. They are $600 new

A new one is almost $1100 these days. Used ones around me are listed for $900+, lol.

- 1

whoo

<Silver Donator>

Verified! I swear I paid 600 for mine, but I'm getting old, sooo...A new one is almost $1100 twhese days. Used ones around me are listed for $900+, lol.

There might be a dowelling tool that works like the Domino, though... I've never looked into it.

Getting 12 dowels along a table edge to line up is a pain in the ass without cheating. I like that the dominos don't lose as much strength with a loose hole (lol) as dowels.Verified! I swear I paid 600 for mine, but I'm getting old, sooo...

There might be a dowelling tool that works like the Domino, though... I've never looked into it.

- 1

Internet arguments aside about dowels vs. dominos, at least the domino being a loose tenon allows you flexibility and a little movement to get your alignment down while still providing some benefit to strength.

Jessem has their POCKETMILL system which made the usual rounds on YouTube recently. It seemed like an interesting alternative to Domino and not a replacement.

jessem.com

jessem.com

Rockler also has the Beadlock system which is even less expensive up front.

www.rockler.com

www.rockler.com

Everyone keeps says that the patent exclusivity for Festool will be running out soon and the market will be flooded with actual alternative versions. But I've been reading that for like 5 years it seems.

Jessem has their POCKETMILL system which made the usual rounds on YouTube recently. It seemed like an interesting alternative to Domino and not a replacement.

Pocket Mill Pro - Loose Tenon System (Backordered)

JessEm is proud to launch the Pocket Mill Pro Loose Tenon Joinery System. No matter what your skill level, the Pocket Mill Pro will make high quality accurate mortises with a simple hand drill.

Rockler also has the Beadlock system which is even less expensive up front.

Rockler Beadlock Pro Jig With 3/8 Kit and Case

Drill specially-shaped mortises to accept Beadlock loose tenons — creates incredibly strong, concealed joints!

Everyone keeps says that the patent exclusivity for Festool will be running out soon and the market will be flooded with actual alternative versions. But I've been reading that for like 5 years it seems.

- 1

Share: