whoo

<Silver Donator>

Oh and look at this: Grappling With Graphite: A Machining Guide - In The Loupe

You may know all this but i learned some stuff!

You may know all this but i learned some stuff!

- 1

Wow, thanks for the rundown.I just did this analysis. My use cases (furniture/carvings) are not yours. However, I have some general observations:

1. Dont assume that all electronics (controller hardware) is equal. The controller has a big impact on the accuracy/speed of job processing. And make sure you have a post processor that supports the software you plan to use to generate your GCode (this is software and usually provided by the manufacturer).

2. Requiring mixed mode operation (mill / laser / plasma) reduces your field considerably.

3. Your budget of 2k won't get you a robust CNC that also runs a laser at sufficient wattage to etch metal. So youre left with a Chinese chinese menu of parts you assemble yourself, or low end setups from decent companies.

4. Another problem is anything under 2k is going to be made of aluminum. Aluminum is strong in crush resistance but weak in torsion (twist). They are hard to keep accurate to .001" otherwise if "good if its within 25 thousandths" is all you need, this is not an issue.

If you're a tinkerer, can navigate linux well enough, or like programming arduino, You'll have more fun building your own robot than making widgets. You have lots of options if this is you.

That said, take a look at avidcnc.com. They make the best aluminum mills ive seen. Easy to choose the options you want, and you assemble the kit. I don't think they have a $2k setup.

I'm curious: is graphite milling easy? It's brittle isnt it?

If you can cut it with a small trim router (16k-20k RPM) and carbide bit, all of them should do it. However, if you're making coin molds of any complexity like heads/hair, small lettering, smooth arcs in Z, it might not be accurate enough to matter.

I think Avid is a good starting point. Also look at vectric.com and check out their VCarve software. This is paid software, but its good.

5. Good results is 50% software mastery, and 50% machine quality. Software is huge. You need Design (CAD), Toolpathing (CAM - that supports laser), special "driver" support for your hardware (post processor- make sure it supports laser). Make sure you know the stack you're going to use.

Hope this was informative. Happy to answer questions. Also I don't want to harsh your tool buzz. CNC is fun

Ok yeah it's low end. All the software is on you. They give you links to FOS software.Wow, thanks for the rundown.

Yeah, from what I am reading graphite mean using a very small bit at a high speed and slow motions, and having an integrated vacuum hood to collect dust as it goes. But those molds like I showed are $100 a pop and I want to get a set where I can select fronts and backs for coin runs which would cost a ton real fast.

Those definitely look better than a lot of what I was considering so far. Here's what the front runner from Amazon was, which I know is a bucket of Chinesium... But apparently with the 300w spindle can work minimal amounts of aluminum, and has a laser option. Amazon product ASIN B0972XW838

I somehow hadn't seen that thread. Thanks! I'll go dive in there.The CNC Thread may get more traffic. Not sure how many people know this Woodworking thread exists.

CNC (Lasers, Routers, Etc)

I don't expect this thread to get too much activity and I could make most of my posts in the 3D printing thread, but I wanted to start collecting the tools/sites that I'm using in one place and I knew I would lose them as random posts in the 3D thread. I'll give a little more backstory when I...www.firesofheaven.org

This thread is reserved for me complaining about the state of my workshop!

j/k! I’ve learned a lot from both threads.

I actually spent yesterday and today setting up my Facebook Marketplace, Instagram Business, and portfolio on Wix. Getting a little more froggy with putting stuff out there and directly soliciting business. Partly because I may soon be changing jobs to independent employment which will give me a revenue stream in the LLC already set up. So I can kind of show profits with the business and offset some loses as I tiptoe in to more commercial / commission work on the furniture side.

For the graphite molds and most other stuff I plan on doing yes.Ok yeah it's low end. All the software is on you. They give you links to FOS software.

Aluminum is so soft i dont doubt it can cut thin sheets. I'm more worried about the graphite and the accuracy. They don't even claim any measure of accuracy.

Also, is a 2" depth of cut enough?

I love buying antique hand tools on eBay. Shit was built to last a lifetime back then and often it's cheaper than whatever chinesium shit that they would sell you at home depot.

Started this thing today. First time I've built anything like this from plans. Probably should have priced it out first.....5x sheets of 3/4in ply. Ouch.

View attachment 431881

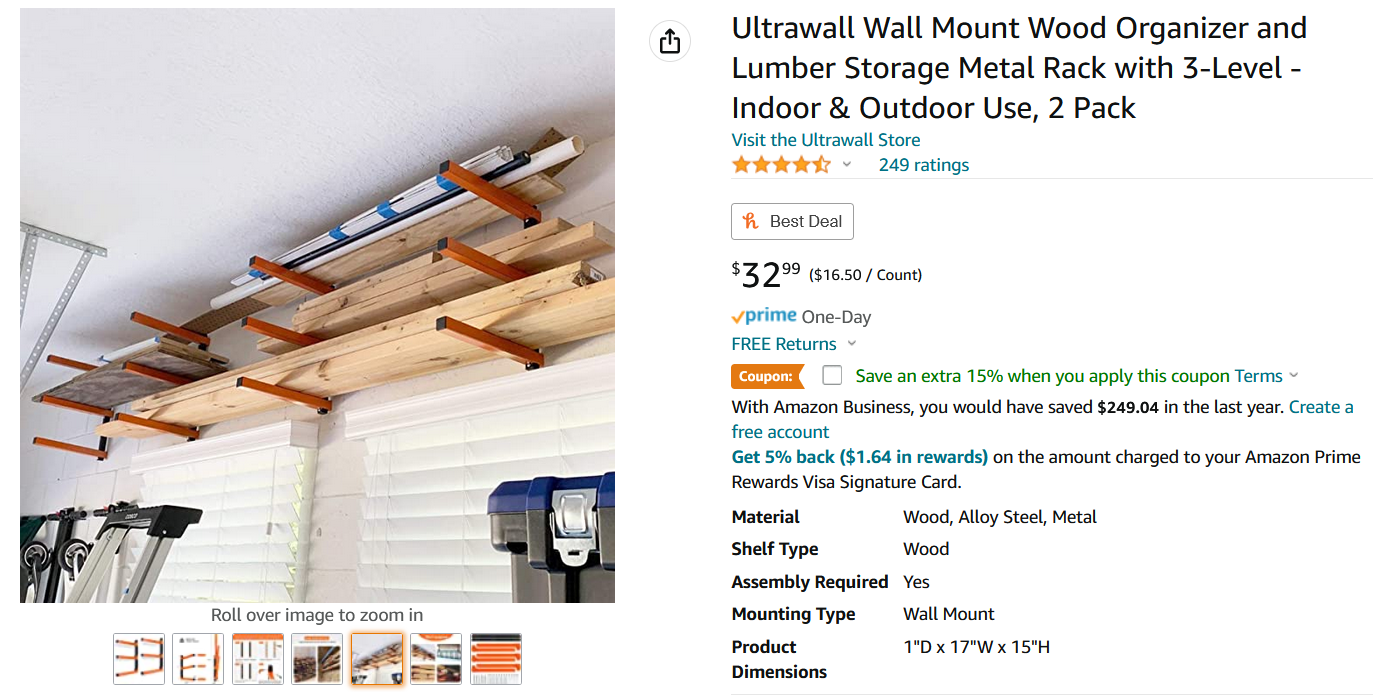

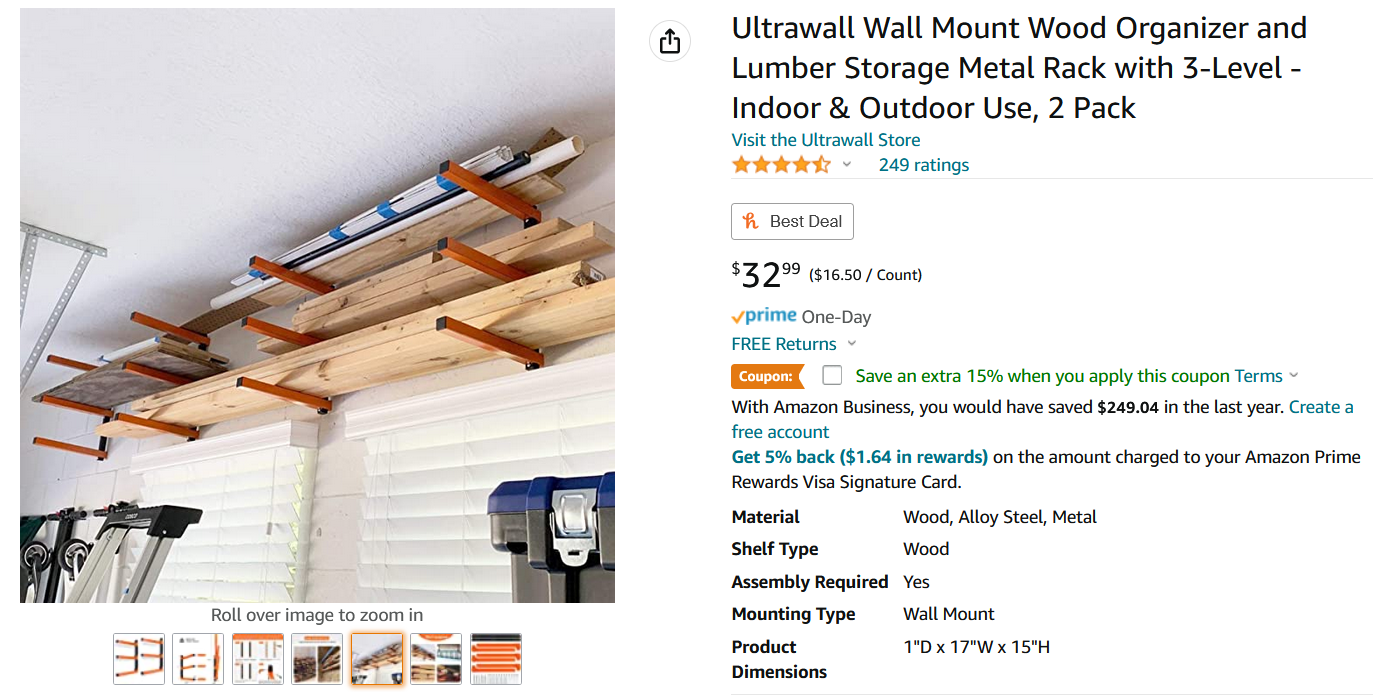

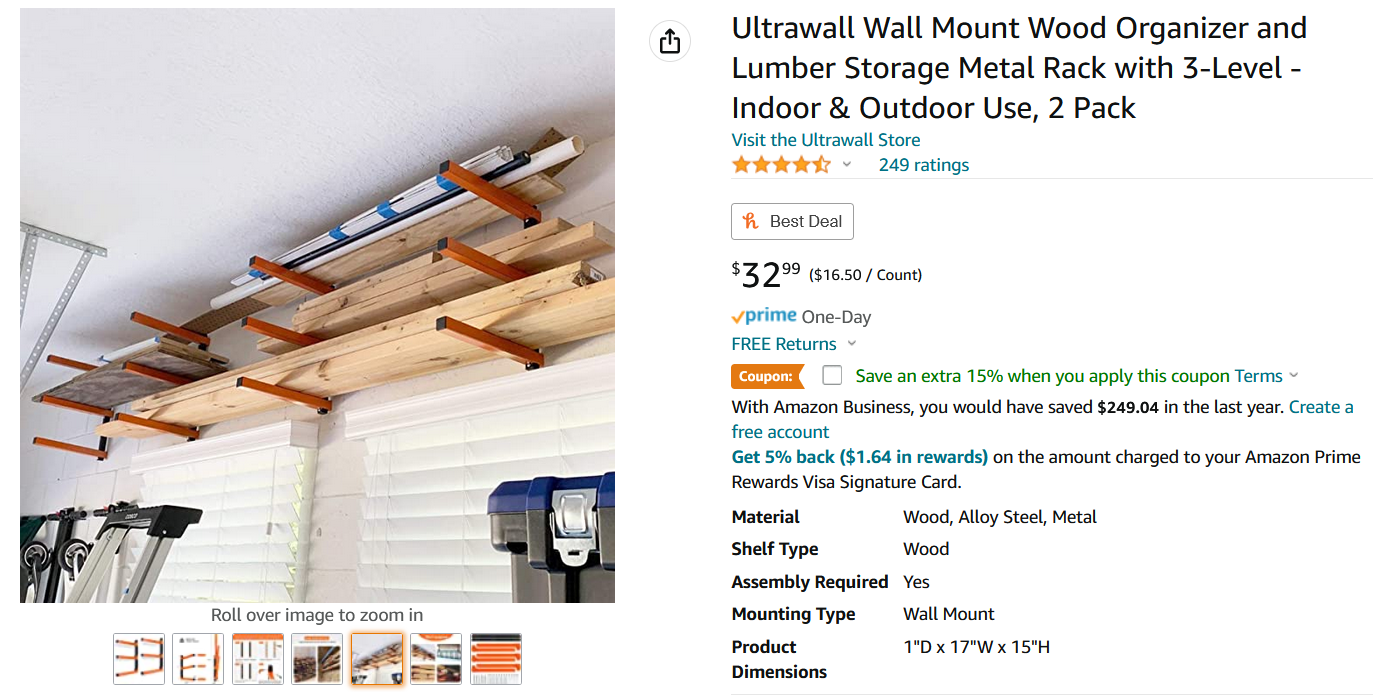

I made a much more rickety version than the one that’s pictured. It’s good for me because it’s on wheels and holds my off cuts that I tend to end up using for various purposes… eventually.I've thought about doing shit like this, but I find that rack would actually take up more space than the wood I have. I don't think there's enough to be gained to do the work and take the expense. Let me know how it goes, and if you like it when you're done.

I made a much more rickety version than the one that’s pictured. It’s good for me because it’s on wheels and holds my off cuts that I tend to end up using for various purposes… eventually.

My situation is helped by the fact that I do actually use them, but probably not in the quantities that I’ve saved themYes, the eventual use...why can't my wife understand that?

while i only have scraps, i used something like this back in old house and wanna do this again to make use of wall space, is this out of the option? admittedly having a requirement to use a ladder really makes it not practical for a person really doing woodstuffsStarted this thing today. First time I've built anything like this from plans. Probably should have priced it out first.....5x sheets of 3/4in ply. Ouch.

View attachment 431881

The beauty of storing scraps/off cuts is that you will inherently not need to access them frequently. Shelves like that wouldn’t work for me because of the lower weight capacity. It would be better than nothing and have the silver lining of forcing you to really assess what’s worth keeping around and what’s not.while i only have scraps, i used something like this back in old house and wanna do this again to make use of wall space, is this out of the option? admittedly having a requirement to use a ladder really makes it not practical for a person really doing woodstuffs

while i only have scraps, i used something like this back in old house and wanna do this again to make use of wall space, is this out of the option? admittedly having a requirement to use a ladder really makes it not practical for a person really doing woodstuffs

at least a sturdy step ladder