The price of a patio sectional is crazy where I am (or maybe just everywhere?). I'm considernig building one - I have a piece of 3" foam I can turn into cushions.

Something like this:

View attachment 415219

My qustion is - would having 3" foam sitting on just wood boards be very comfy? I know a lot of sectional use wicker. Is there another solution I can put as the surface of the sectional or you think the planks are fine?

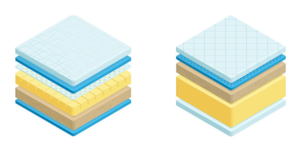

As Goatface was hinting at, it all depends on the foam, but don't expect miracles by just using foam on top of wood. Also, foam varies substantially in softness and most manufacturers of good seat cushions will use at least two types of foam in layers, if not 3 or 4 (1+ inch thick layers, or a firmer thicker layer sandwiched between 2 thinner softer layers). If you are too heavy for the foam you will just sink through it all and if you are too light, it wont be much better than wood (link to explanation of foam weights and durability at the bottom).

The best bet, if you want want a softer sit, is to use the jute/upholstery webbing method, instead of straight wood, under the foam. I think many of the commercially sold outside couches use this method with a piece of cloth over the webbing. Main downside is that it will probably rot faster than the wood (same rate as the cushion fabric, maybe). The more webbing you use (the closer the weave), the firmer the base will be.

They are going to use springs, along with the webbing for this ottoman, so they are putting the webbing on the bottom, but it's still a good tutorial on one way to attach them (only 480p):

Longer full tutorial in 720:

About foam:

Here are two decent write ups on the various foams for upholstery:

Density and firmness are two separate but important measurements of foam. Here's a simple explanation of foam firmness and foam density. An easy guide.

foamhow.com

Looking for your next foam mattress purchase but unsure about some key terms? We'll help you learn about foam density, weight, and firmness.

foamonline.com

Here is an idea of prices for each (I think I have purchased from them, or at least it was bookmarked):

Our high-density foam is great for mattresses, cars, chair pads, boat cushions, church pews, upholstery shops, camping, packaging, massage tables.

foamforyou.com